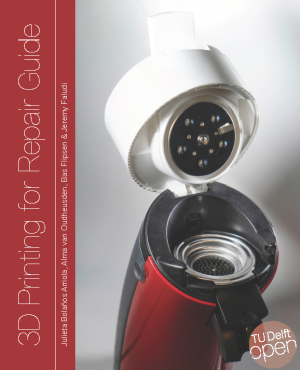

3D Printing for Repair Guide

Synopsis

This guide takes the reader through the 3D Printing for Repair (3DP4R) process. It consists of guidelines and tools to create a 3D printable version of spare parts needed for a product repair. 3D printing a spare part is more than just printing the original part. Instead, it is an iterative process in which the part is analysed, redesigned, manufactured, and tested, in order to come to a final part. This guide will describe these four phases in detail. The guide is meant for anybody who is interested in trying to manufacture spare parts with 3D printing technologies, remakers, tinkerers, volunteer repairers, professional repairers, and everyone who is interested in repair initiatives.

Downloads

References

“SHAREPAIR - Digital Support Infrastructure for Citizens in the Repair Economy - Project Summary,” Interreg NWE Sharepair, 2021. [Online]. Available: https://www.nweurope.eu/projects/project-search/sharepair-digital-support-infrastructure-for-citizens-in-the-repair-economy/. [Accessed 15 December 2021].

J. Maxham, “The Art Of Troubleshooting,” [Online]. Available: https://artoftroubleshooting.com/. [Accessed 1 February 2022].

Makerbot Thingiverse, “Thingiverse,” MakerBot Industries, LLC , 2022. [Online]. Available: https://www.thingiverse.com/tag:repair. [Accessed 1 February 2022].

GrabCAD, “GrabCAD,” Stratasys, 2022. [Online]. Available: https://grabcad.com/library/tag/repair. [Accessed 1 February 2022].

MyMiniFactory, “MyMiniFactory,” MyMiniFactory, 2022. [Online]. Available: https://www.myminifactory.com/category/brands-spare-parts. [Accessed 1 February 2022].

“SHAREPAIR @ MyMiniFactory,” MyMiniFactory, 2021. [Online]. Available: https://www.myminifactory.com/users/SHAREPAIR. [Accessed 15 December 2021].

M. T. F. Beerkens, “Repair Using 3D Printing: 1 Decomposition,” Instructables, 2017. [Online]. Available: https://www.instructables.com/Repair-Using-3D-Printing-1-Decomposition/. [Accessed 15 December 2021].

iFixit, “Repair guides,” iFixit, 2022. [Online]. Available: https://www.ifixit.com/Guide. [Accessed 1 February 2022].

Prusa, “FAQ - Frequently Asked Questions,” Prusa Research a.s., 2021. [Online]. Available: https://help.prusa3d.com/en/article/faq-frequently-asked-questions_1932#. [Accessed 1 February 2022].

Woakamkurhram, “HK Plastic Recycling mark black food container Resin identification code 1 PET,” Wikimedia Commons, 28 February 2014. [Online]. Available: https://commons.wikimedia.org/wiki/File:HK_Plastic_Recycling_mark_black_food_container_Resin_identification_code_1_PET_in_Feb-2014.JPG. [Accessed 15 December 2021].

Plastic Soup Foundation, “Recycling codes,” Plastic Soup Foundation, [Online]. Available: https://www.plasticsoupfoundation.org/en/plastic-problem/what-is-plastic/recycling-codes/. [Accessed 1 February 2022].

Materialise, “Materialise,” Materialise, 2022. [Online]. Available: https://www.materialise.com/. [Accessed 1 February 2022].

D HUBS B.V., “Hubs,” 3D HUBS B.V., 2022. [Online]. Available: https://www.hubs.com/. [Accessed 1 February 2022].

A. B. Varotsis, “Selecting the right 3D printing process,” 3D HUBS B.V., 2022. [Online]. Available: https://www.3dhubs.com/knowledge-base/selecting-right-3d-printing-process/. [Accessed 1 February 2022].

InjectionMoulding.org, “Plastic Injection Mould Making in China,” InjectionMoulding.org, 2022. [Online]. Available: http://www.injectionmoulding.org/plastic-injection-mould-making-in-china.html. [Accessed 1 February 2022].

InjectionMoulding.org, “Precision Injection Moulding,” InjectionMoulding.org, 2022. [Online]. Available: http://www.injectionmoulding.org/precision-injection-moulding.html . [Accessed 1 February 2022].

R. Brockotter, “Design Guidelines - Key design considerations for 3D printing,” 3D Hubs, 2021. [Online]. Available: https://www.hubs.com/knowledge-base/key-design-considerations-3d-printing/. [Accessed 15 December 2021].

P. Cain, “Selecting the optimal shell and infill parameters for FDM 3D printing,” 3DHubs B.V., 2021. [Online]. Available: https://www.3dhubs.com/knowledge-base/selecting-optimal-shell-and-infill-parameters-fdm-3d-printing/. [Accessed 15 December 2021].

B. Redwood, “Quick tips before you start - How does part orientation affect a 3D print,” 3D Hubs, 2021. [Online]. Available: https://www.hubs.com/knowledge-base/how-does-part-orientation-affect-3d-print/. [Accessed 15 December 2021].

M. T. F. Beerkens, “Application of 3D printing in Repair,” Delft University of Technology, 2017.

M. T. F. Beerkens, “Repair Using 3D Printing: 2a 3D Scanning,” Instructables, 2017. [Online]. Available: https://www.instructables.com/Repair-Using-3D-Printing-2a-3D-Scanning/. [Accessed 15 December 2021].

AliceVision, “Meshroom,” AliceVision, [Online]. Available: https://alicevision.org/#meshroom. [Accessed 15 December 2021].

Regard3D, “Regard3D,” Regard3D, [Online]. Available: http://www.regard3d.org/index.php. [Accessed 15 December 2021].

P. 3. b. J. Prusa, “Photogrammetry 2 – 3D scanning with just PHONE/CAMERA simpler, better than ever!,” YouTube, 7 December 2018. [Online]. Available: https://www.youtube.com/watch?v=1D0EhSi-vvc&ab_channel=Prusa3DbyJosefPrusa. [Accessed 15 December 2021].

C. Kraft, “Preserving Sculptures With 3D Scanning And 3D Printing,” Make Community LLC, 1 December 2020. [Online]. Available: https://makezine.com/2020/12/01/preserving-sculptures-with-3d-scanning-and-3d-printing/. [Accessed 15 December 2021].

B. Weld, “How to Read a Metric Vernier Caliper,” YouTube, 10 February 2017. [Online]. Available: https://www.youtube.com/watch?v=vkPlzmalvN4&ab_channel=WeldNotes. [Accessed 1 February 2022].

Autodesk TinkerCAD, “Autodesk TinkerCAD,” Autodesk, Inc., 2021. [Online]. Available: https://www.tinkercad.com/. [Accessed 15 December 2021].

D Slash, “3D Slash,” 3D Slash, 2021. [Online]. Available: https://www.3dslash.net/index.php. [Accessed 15 December 2021].

Dassault Systèmes SolidWorks Corporation, “SOLIDWORKS,” Dassault Systèmes SolidWorks Corporation, [Online]. Available: https://www.solidworks.com/. [Accessed 15 December 2021].

Robert McNeel & Associates, “Rhino - Rhinoceros 3D,” Rhinoceros, 2021. [Online]. Available: https://www.rhino3d.com/. [Accessed 15 December 2021].

Robert McNeel & Associates, “Rhino - Grasshopper,” Rhinoceros, 2021. [Online]. Available: https://www.rhino3d.com/6/new/grasshopper/.

Autodesk Inc., “Fusion 360 for personal use,” Autodesk Inc., 2021. [Online]. Available: https://www.autodesk.com/products/fusion-360/personal. [Accessed 15 December 2021].

Onshape Inc., “Onshape Free,” Onshape Inc., 2021. [Online]. Available: https://www.onshape.com/en/products/free. [Accessed 15 December 2021].

The FreeCAD Team, “FreeCAD: Your own 3D parametric modeler,” The FreeCAD Team, [Online]. Available: https://www.freecadweb.org/. [Accessed 15 December 2021].

M. Kintel, “OpenSCAD - The Programmers Solid 3D CAD Modeller,” OpenSCAD, [Online]. Available: http://openscad.org/index.html. [Accessed 15 December 2021].

MakerBot Thingiverse, “Thingiverse,” MakerBot Industries, LLC, [Online]. Available: https://www.thingiverse.com/. [Accessed 15 December 2021].

MakerBot Thingiverse, “Customizer,” MakerBot Industries, LLC, 2021. [Online]. Available: https://www.thingiverse.com/app:22. [Accessed 15 December 2021].

Autodesk, Inc., “Autodesk Meshmixer: free software for making awesome stuff,” Autodesk, Inc., 2020. [Online]. Available: https://www.meshmixer.com/. [Accessed 15 December 2021].

Sharepair, “3D Printing for Repair Guidance | 1. Intro,” YouTube, 24 November 2021. [Online]. Available: https://www.youtube.com/watch?v=WTkv02Y1lP0&ab_channel=IDETUDelft. [Accessed 15 December 2021].

Make With Tech (MakeWithTech), “Getting Started with Tinkercad for Adults,” YouTube, 8 February 2019. [Online]. Available: https://www.youtube.com/watch?v=n71PFgQ0z5A. [Accessed 15 December 2021].

Jayanam, “Fusion 360 Getting Started Tutorial,” YouTube, 5 March 2019. [Online]. Available: https://www.youtube.com/watch?v=Vkt7DN3GzQY. [Accessed 15 December 2021].

bmgsTECH, “Onshape.com - Getting Started,” YouTube, 24 February 2017. [Online]. Available: https://www.youtube.com/watch?v=U5R33hR51Vw. [Accessed 15 December 2021].

Make With Tech (MakeWithTech), “FreeCAD for Beginners | 3d Printing | Basics,” YouTube, 2 July 2020. [Online]. Available: https://www.youtube.com/watch?v=6JOITgw_T1Y. [Accessed 15 December 2021].

Open-SCAD DIY3DTech, “Open SCAD - Introduction Part 1 for New Users!,” YouTube, 12 February 2018. [Online]. Available: https://www.youtube.com/watch?v=RUXHpmhfVyg. [Accessed 15 December 2021].

d Matter, “FDM 3D printing materials compared,” 3D HUBS B.V., 2021. [Online]. Available: https://www.hubs.com/knowledge-base/fdm-3d-printing-materials-compared/. [Accessed 15 December 2021].

Ultimaker BV, “Ultimaker Cura,” Ultimaker BV, 2021. [Online]. Available: https://ultimaker.com/software/ultimaker-cura. [Accessed 15 December 2021].

Dwamena, “What is the Strongest Infill Pattern?,” 3D Printerly, [Online]. Available: https://3dprinterly.com/what-is-the-strongest-infill-pattern/. [Accessed 2 February 2022].

Sharepair, “3D Printing for Repair Guidance | 6. From Redesign to Manufacture,” YouTube, 24 November 2021. [Online]. Available: https://www.youtube.com/watch?v=SrF8sYSJhgw. [Accessed 15 December 2021].

A. Williams, “Reforming 3D Prints With Salt And Heat,” Hackaday, 23 September 2020. [Online]. Available: https://hackaday.com/2020/09/23/reforming-3d-prints-with-salt-and-heat/. [Accessed 15 December 2021].